From Drone Surveys to Stockpile Volumes and Terrain Analysis

Why Mining Needs LiDAR

Mining operations generate constantly changing terrain. Pits expand, stockpiles grow and shrink, haul roads shift. Accurate, up-to-date terrain data is essential.

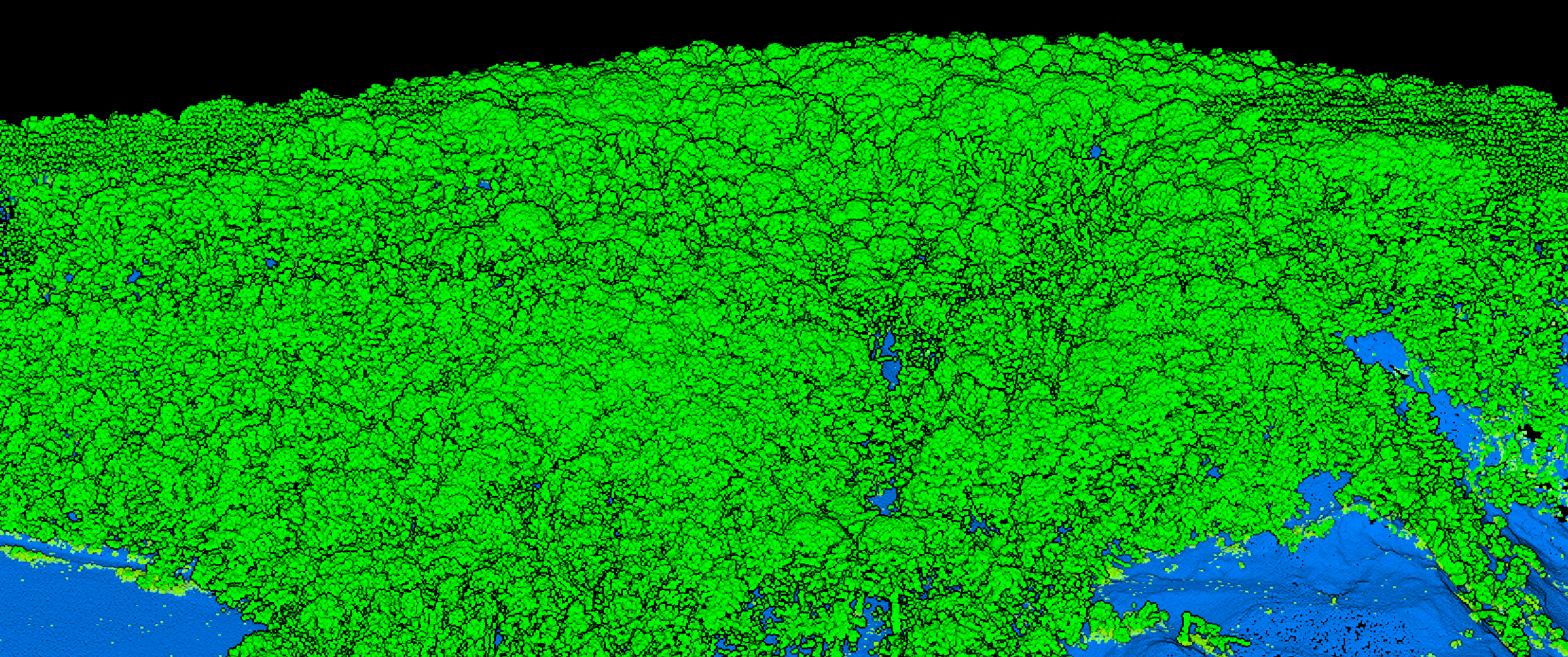

Mining site point cloud with vegetation visible

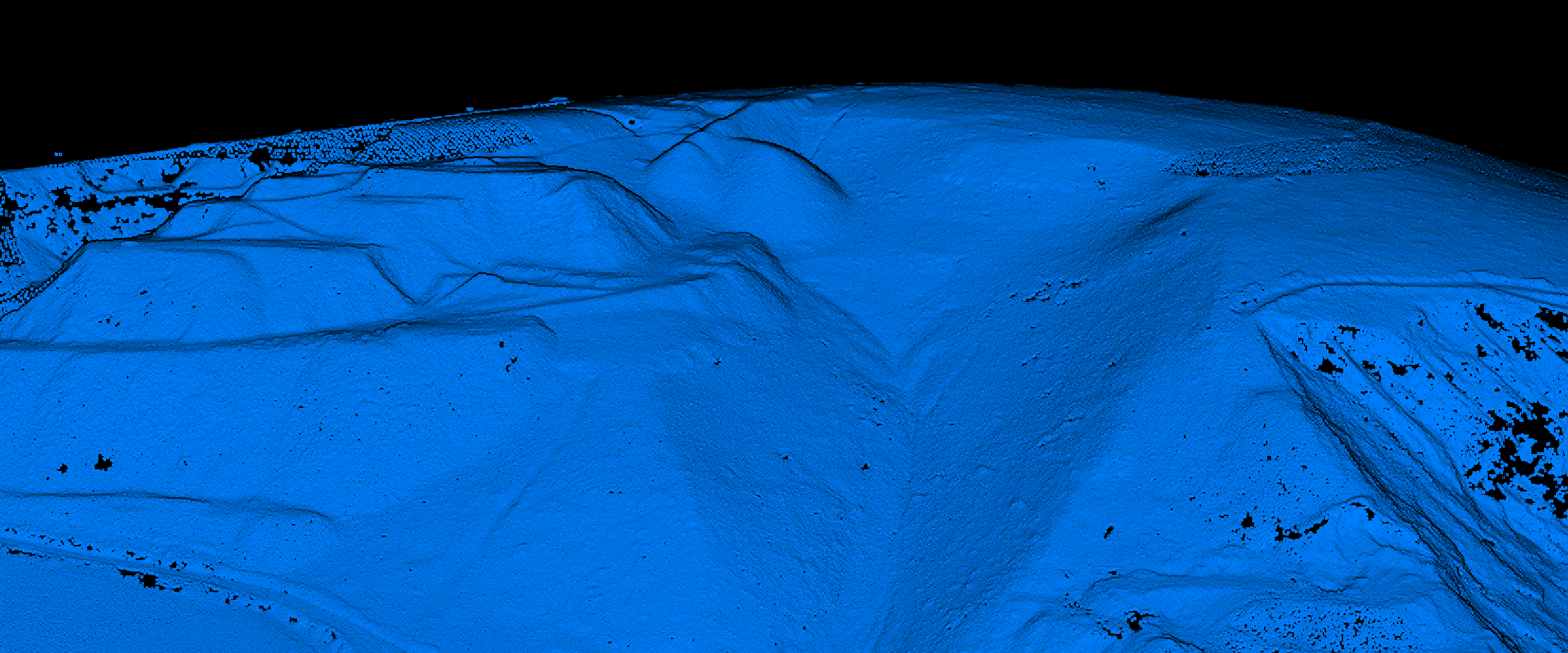

Same site with vegetation filtered for terrain analysis

LiDAR Advantages for Mining

Speed

Survey an entire open-pit mine in a single day. Traditional ground surveys take two weeks.

Safety

No personnel on unstable slopes, near blasting zones, or in active pit areas. Drones capture data safely.

Accuracy

Centimeter-level accuracy critical for volume calculations. 5cm error over 100,000m³ = thousands of m³ discrepancy.

Dense Data

Millions of points per survey. Works reliably on uniform surfaces where photogrammetry struggles.

Key Mining Applications

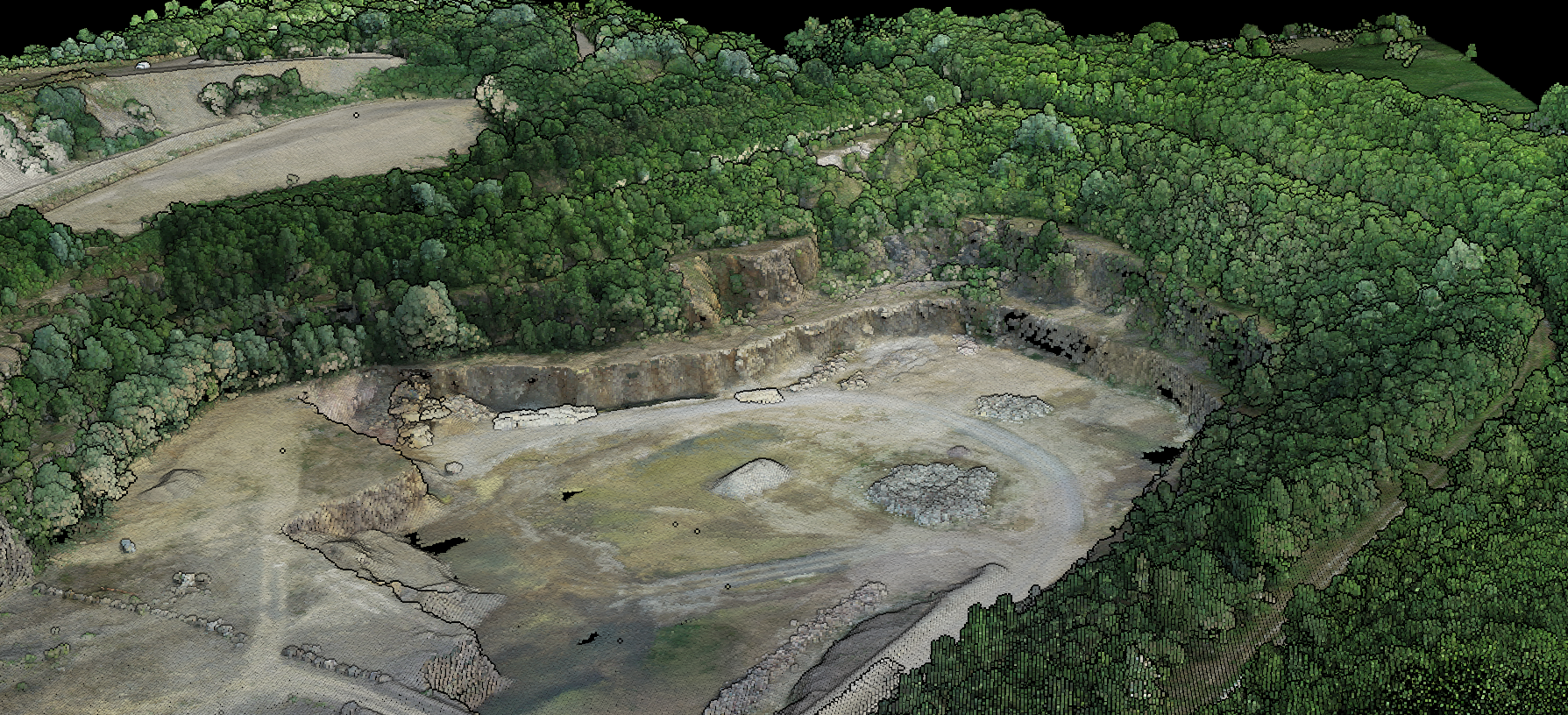

Stockpile Volume Measurement

Essential for inventory management and financial reporting. LiDAR captures complete surface for accurate volume calculations.

Pit Slope Monitoring

Maintain pit wall angles within geotechnical limits. Detect movement and instability before failures occur.

Terrain Analysis Outputs

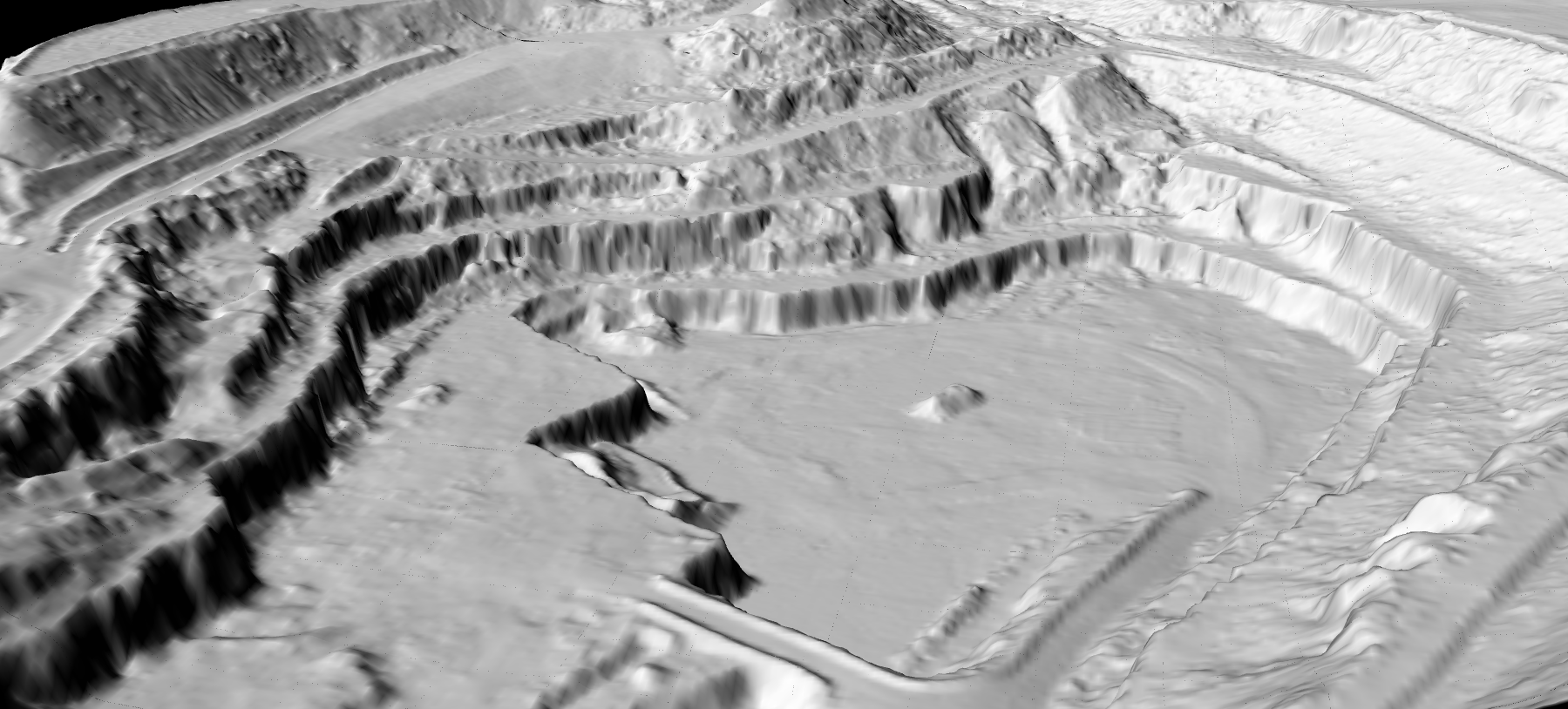

Digital Terrain Model (DTM)

Bare-earth elevation model essential for volume calculations and pit design. Vegetation automatically filtered.

Slope Analysis

Identify unstable areas, plan haul roads, and ensure pit walls meet safety requirements with detailed slope maps.

DTM derived from mining site LiDAR data

Create a FREE account now and start processing your point cloud

Get 2 GB of storage space and classify up to 10 hectares for free.